Chip capacitors are essential components in modern electronic circuits, playing a critical role in everything from power supply filtering to signal processing. As electronics continue to evolve, so too does the technology behind these tiny yet vital components. The latest advancements in chip capacitor technology are pushing the boundaries of performance, size, and reliability, enabling more sophisticated and compact electronic devices. In this blog, we’ll explore some of the most significant recent innovations in chip capacitor technology and what they mean for the future of electronics.

- Miniaturization and High Capacitance in Smaller Footprints

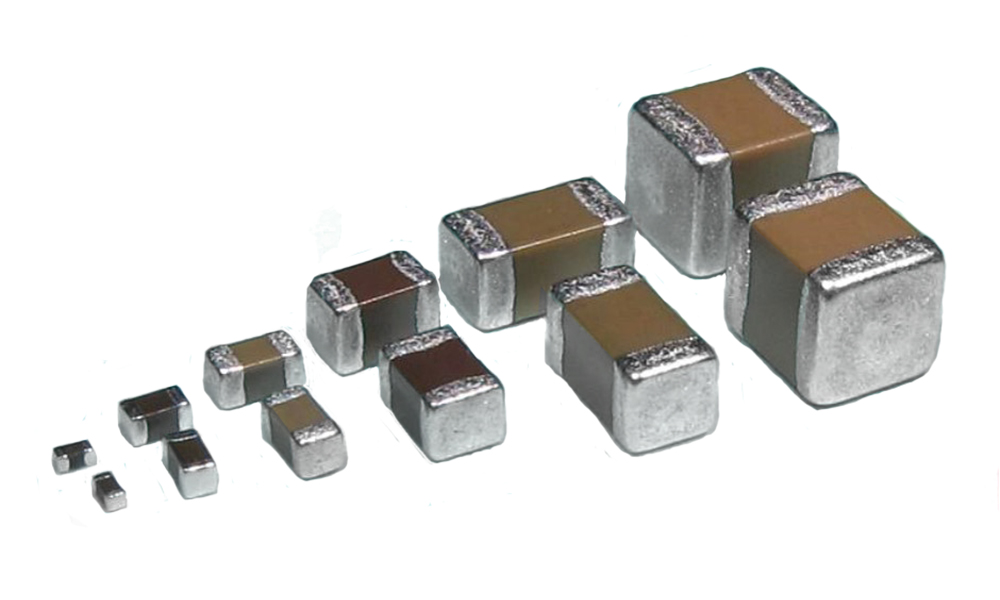

As electronic devices become increasingly compact, the demand for smaller components with higher performance has intensified. One of the key advancements in chip capacitor technology is the ability to achieve higher capacitance values in smaller footprints. Manufacturers are now producing multi-layer ceramic capacitors (MLCCs) that offer significant capacitance in ultra-compact packages. This miniaturization is achieved through advanced materials and manufacturing techniques, such as thinner dielectric layers and more efficient stacking of multiple layers.

What This Means: Engineers can now design smaller, more efficient circuits without sacrificing performance, which is particularly beneficial in applications like smartphones, wearable devices, and IoT gadgets.

- Improved Dielectric Materials

The dielectric material used in a chip capacitor is crucial to its performance, influencing factors like capacitance, voltage rating, and temperature stability. Recent advancements have focused on developing new dielectric materials that offer better performance characteristics. For example, some manufacturers are using advanced ceramics and polymers that provide higher capacitance stability over a wider temperature range, lower equivalent series resistance (ESR), and improved reliability under high-stress conditions.

What This Means: Enhanced dielectric materials lead to more reliable capacitors that can operate effectively in harsh environments, making them ideal for automotive, aerospace, and industrial applications.

- Increased Voltage Ratings

Another significant advancement in chip capacitor technology is the development of capacitors with higher voltage ratings. Traditionally, increasing voltage ratings meant larger capacitors, but new manufacturing techniques now allow for higher voltage capacitors without a corresponding increase in size. This is particularly important for power electronics and energy storage systems where high voltage capacitors are essential.

What This Means: Designers can now incorporate high voltage capacitors into compact designs, enabling more efficient power management in applications such as electric vehicles, renewable energy systems, and high-power telecommunications equipment.

- Low ESL (Equivalent Series Inductance) Designs

In high-frequency applications, the equivalent series inductance (ESL) of a capacitor becomes a critical factor. High ESL can lead to performance issues such as resonances and reduced effectiveness of the capacitor at filtering or bypassing high-frequency signals. Recent innovations have focused on reducing the ESL in chip capacitors, often through novel internal electrode designs and optimized terminal configurations.

What This Means: Capacitors with low ESL are essential for high-speed digital circuits, RF applications, and signal integrity in high-frequency designs, allowing for more precise and reliable operation.

- Enhanced Reliability and Longevity

As electronic devices are expected to last longer, especially in critical applications like medical devices and automotive systems, the reliability and longevity of chip capacitors have become paramount. Recent advancements include improvements in materials, manufacturing processes, and testing methodologies that ensure capacitors can withstand more cycles of thermal and mechanical stress without degradation.

What This Means: Enhanced reliability ensures that devices function correctly over longer periods, reducing the need for maintenance and replacements, which is particularly valuable in mission-critical applications.

- Environmental and Sustainability Innovations

The electronics industry is increasingly focused on sustainability, and chip capacitor manufacturers are responding with innovations that reduce environmental impact. This includes the use of lead-free materials, reduction in hazardous substances, and more energy-efficient manufacturing processes. Some companies are also exploring the use of recyclable or biodegradable materials for capacitor packaging.

What This Means: Environmentally friendly capacitors help reduce the ecological footprint of electronic devices, aligning with global efforts to promote sustainable manufacturing and reduce electronic waste.

- Integration with Advanced Packaging Technologies

As the demand for more integrated and multi-functional components grows, chip capacitors are being developed to work seamlessly with advanced packaging technologies. This includes integration into system-in-package (SiP) and system-on-chip (SoC) designs, where capacitors are embedded directly into the substrate or package, further reducing space and improving performance.

What This Means: Integration with advanced packaging allows for more compact and efficient designs, supporting the trend toward miniaturization and multifunctionality in consumer electronics, medical devices, and more.

Conclusion

The continuous advancements in chip capacitor technology are not only enabling the creation of more powerful, reliable, and compact electronic devices but are also pushing the boundaries of what’s possible in electronic design. Whether it’s through miniaturization, improved materials, or enhanced reliability, these innovations are setting the stage for the next generation of electronics that are smaller, faster, and more efficient than ever before. As technology continues to evolve, chip capacitors will remain at the forefront, driving progress in countless applications and industries.